Special Design for Aem Rubber - General Molding Solid Precipitated Silicone Compound – FUDI

Stock Sample is Free & Available

Special Design for Aem Rubber - General Molding Solid Precipitated Silicone Compound – FUDI Detail:

Silicone rubber is non-reactive, stable, and resistant to extreme environments and temperatures from −55 to 300 °C (−67 to 572 °F) while still maintaining its useful properties. It can be found in a wide variety of products, including: voltage line insulators, automotive applications; cooking, baking, and food storage products; electronics; medical devices and implants, etc.

General application silicone

● Good processing performance

● Good stability

● Good resilience

● Good fluidity

● Fast curing speed

● Good mould-releasing

● FDA, Rohs certified

Technical Data

| Items |

|

|

Value |

||||

| TN-720 | TN-730 | TN-740 | TN-750 | TN-760 | TN-770 | TN-780 | |

| Appearance |

Translucent, smooth surface, no impurities |

||||||

| Density (g/cm3) | 1.06±0.03 | 1.08±0.03 | 1.12±0.03 | 1.15±0.03 | 1.19±0.03 | 1.22±0.03 | 1.24±0.03 |

| Hardness (Shore A) | 20±2 | 30±2 | 40±2 | 50±2 | 60±2 | 70±2 | 80±2 |

| Tensile strength (Mpa)≥ | 4.0 | 6.0 | 6.5 | 7.5 | 7.5 | 7.0 | 7.0 |

| Elongation(%)≥ | 750 | 650 | 550 | 450 | 400 | 280 | 150 |

| Tear strength (kN/m)≥ | 8 | 10 | 10 | 12 | 10 | 10 | 8 |

| Shrinkage(%) | 3.7~4.3 | 3.6~34.1 | 3.3~3.9 | 3.1~3.7 | 2.9~3.5 | 2.8~3.4 | 2.7~3.3 |

| Plasticity | 120~150 | 135~160 | 165~195 | 200~230 | 235~255 | 290~320 | 315~345 |

Packing

20kgs per carton, 1000kgs per pallet

Storage

Shall be put in dry and ventilate places. Validity is 6 months.

Application

Cake plates, other sealing parts.

Fumed extrusion silicone

● High extrusion speed, no bubble, smooth surface, good processing performance.

● FDA, LFGB, ROHS, REACH certificated

Application

Suitable for extruding rubber hose, sealing strip, etc.

| Items |

|

|

Value |

||

| TN-930 | TN-730 | TN-950 | TN-960 | TN-970 | |

| Appearance |

Transparent solid |

||||

| Density (g/cm3) | 1.09±0.03 | 1.1±0.03 | 1.12±0.03 | 1.13±0.03 | 1.15±0.03 |

| Hardness (Shore A) | 30±2 | 40±2 | 50±2 | 60±2 | 70±2 |

| Tensile strength (Mpa)≥ | 6 | 6.5 | 7 | 7 | 7.5 |

| Elongation(%)≥ | 450 | 350 | 250 | 200 | 150 |

| Tear strength (kN/m)≥ | 10 | 10 | 12 | 12 | 15 |

| Shrinkage(%) | 3.5~4.1 | 3.3~3.9 | 3.1~3.7 | 3.0~3.6 | 2.8~3.4 |

| Plasticity | 140~170 | 170~190 | 170~200 | 190~230 | 220~260 |

Other grades silicone we provide:

Platinum silicone rubber

Liquid silicone rubber

Fumed silicone rubber

Precipitated silicone rubber

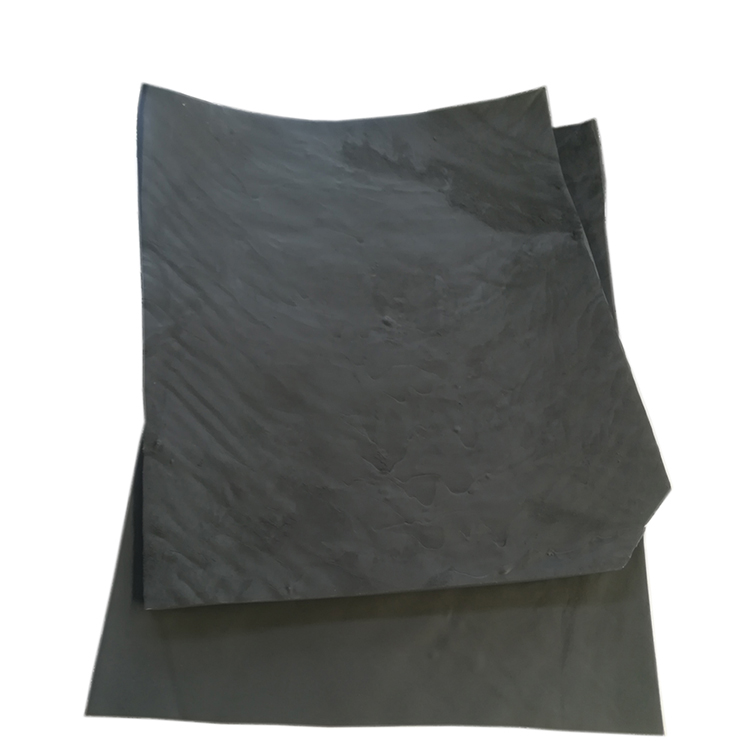

Product detail pictures:

Related Product Guide:

We are proud of the superior customer gratification and wide acceptance due to our persistent pursuit of top of the range both of those on merchandise and service for Special Design for Aem Rubber - General Molding Solid Precipitated Silicone Compound – FUDI , The product will supply to all over the world, such as: Danish, US, Turkey, They're durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it's a really should in your case of excellent good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We're confident that we've been planning to possess a vibrant prospect and to be distributed all over the world within the years to come.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.