Personlized Products Fpm Seal Material - General Molding Solid Precipitated Silicone Compound – FUDI

Stock Sample is Free & Available

Personlized Products Fpm Seal Material - General Molding Solid Precipitated Silicone Compound – FUDI Detail:

Silicone rubber is non-reactive, stable, and resistant to extreme environments and temperatures from −55 to 300 °C (−67 to 572 °F) while still maintaining its useful properties. It can be found in a wide variety of products, including: voltage line insulators, automotive applications; cooking, baking, and food storage products; electronics; medical devices and implants, etc.

General application silicone

● Good processing performance

● Good stability

● Good resilience

● Good fluidity

● Fast curing speed

● Good mould-releasing

● FDA, Rohs certified

Technical Data

| Items |

|

|

Value |

||||

| TN-720 | TN-730 | TN-740 | TN-750 | TN-760 | TN-770 | TN-780 | |

| Appearance |

Translucent, smooth surface, no impurities |

||||||

| Density (g/cm3) | 1.06±0.03 | 1.08±0.03 | 1.12±0.03 | 1.15±0.03 | 1.19±0.03 | 1.22±0.03 | 1.24±0.03 |

| Hardness (Shore A) | 20±2 | 30±2 | 40±2 | 50±2 | 60±2 | 70±2 | 80±2 |

| Tensile strength (Mpa)≥ | 4.0 | 6.0 | 6.5 | 7.5 | 7.5 | 7.0 | 7.0 |

| Elongation(%)≥ | 750 | 650 | 550 | 450 | 400 | 280 | 150 |

| Tear strength (kN/m)≥ | 8 | 10 | 10 | 12 | 10 | 10 | 8 |

| Shrinkage(%) | 3.7~4.3 | 3.6~34.1 | 3.3~3.9 | 3.1~3.7 | 2.9~3.5 | 2.8~3.4 | 2.7~3.3 |

| Plasticity | 120~150 | 135~160 | 165~195 | 200~230 | 235~255 | 290~320 | 315~345 |

Packing

20kgs per carton, 1000kgs per pallet

Storage

Shall be put in dry and ventilate places. Validity is 6 months.

Application

Cake plates, other sealing parts.

Fumed extrusion silicone

● High extrusion speed, no bubble, smooth surface, good processing performance.

● FDA, LFGB, ROHS, REACH certificated

Application

Suitable for extruding rubber hose, sealing strip, etc.

| Items |

|

|

Value |

||

| TN-930 | TN-730 | TN-950 | TN-960 | TN-970 | |

| Appearance |

Transparent solid |

||||

| Density (g/cm3) | 1.09±0.03 | 1.1±0.03 | 1.12±0.03 | 1.13±0.03 | 1.15±0.03 |

| Hardness (Shore A) | 30±2 | 40±2 | 50±2 | 60±2 | 70±2 |

| Tensile strength (Mpa)≥ | 6 | 6.5 | 7 | 7 | 7.5 |

| Elongation(%)≥ | 450 | 350 | 250 | 200 | 150 |

| Tear strength (kN/m)≥ | 10 | 10 | 12 | 12 | 15 |

| Shrinkage(%) | 3.5~4.1 | 3.3~3.9 | 3.1~3.7 | 3.0~3.6 | 2.8~3.4 |

| Plasticity | 140~170 | 170~190 | 170~200 | 190~230 | 220~260 |

Other grades silicone we provide:

Platinum silicone rubber

Liquid silicone rubber

Fumed silicone rubber

Precipitated silicone rubber

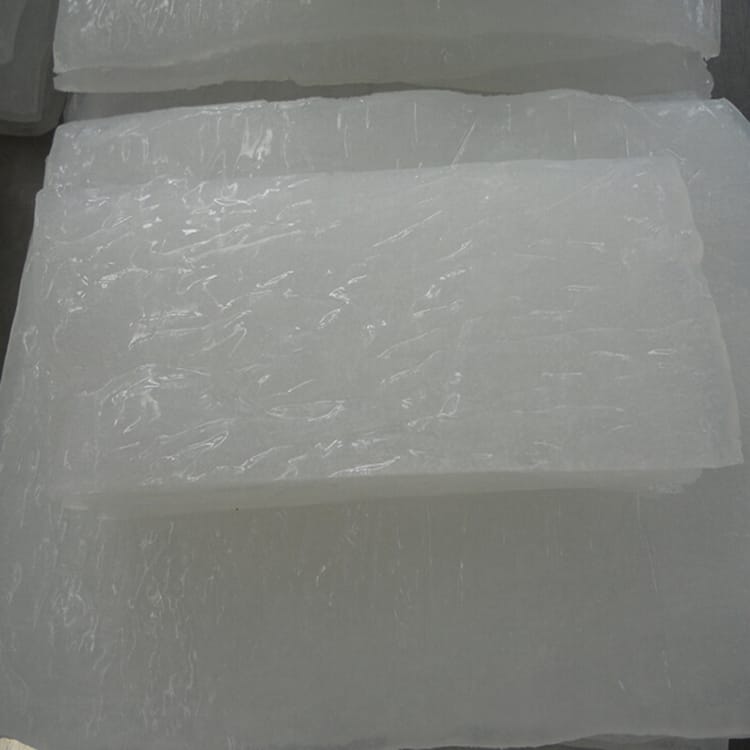

Product detail pictures:

Related Product Guide:

Attaining consumer satisfaction is our company's purpose without end. We will make wonderful endeavours to produce new and top-quality merchandise, satisfy your exclusive requirements and supply you with pre-sale, on-sale and after-sale services for Personlized Products Fpm Seal Material - General Molding Solid Precipitated Silicone Compound – FUDI , The product will supply to all over the world, such as: South Korea, Milan, Eindhoven, With more and more Chinese products and solutions around the world, our international business is developing rapidly and economic indicators big increase year by year. We have enough confidence to supply you both better solutions and service, because we've been more and more powerful, specialist and experience in domestic and international.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!