OEM manufacturer Unvulcanized Viton - General Molding Solid Precipitated Silicone Compound – FUDI

Stock Sample is Free & Available

OEM manufacturer Unvulcanized Viton - General Molding Solid Precipitated Silicone Compound – FUDI Detail:

Silicone rubber is non-reactive, stable, and resistant to extreme environments and temperatures from −55 to 300 °C (−67 to 572 °F) while still maintaining its useful properties. It can be found in a wide variety of products, including: voltage line insulators, automotive applications; cooking, baking, and food storage products; electronics; medical devices and implants, etc.

General application silicone

● Good processing performance

● Good stability

● Good resilience

● Good fluidity

● Fast curing speed

● Good mould-releasing

● FDA, Rohs certified

Technical Data

| Items |

|

|

Value |

||||

| TN-720 | TN-730 | TN-740 | TN-750 | TN-760 | TN-770 | TN-780 | |

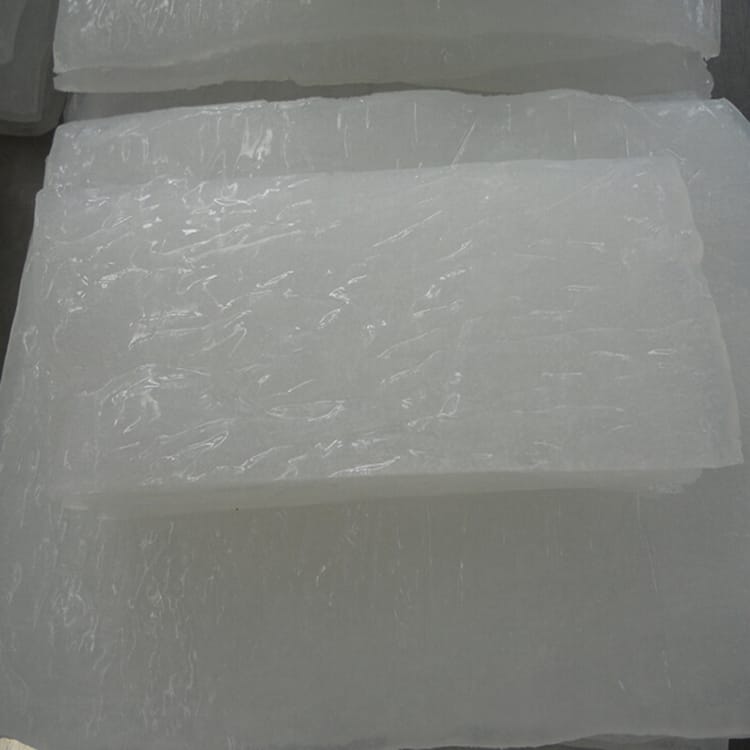

| Appearance |

Translucent, smooth surface, no impurities |

||||||

| Density (g/cm3) | 1.06±0.03 | 1.08±0.03 | 1.12±0.03 | 1.15±0.03 | 1.19±0.03 | 1.22±0.03 | 1.24±0.03 |

| Hardness (Shore A) | 20±2 | 30±2 | 40±2 | 50±2 | 60±2 | 70±2 | 80±2 |

| Tensile strength (Mpa)≥ | 4.0 | 6.0 | 6.5 | 7.5 | 7.5 | 7.0 | 7.0 |

| Elongation(%)≥ | 750 | 650 | 550 | 450 | 400 | 280 | 150 |

| Tear strength (kN/m)≥ | 8 | 10 | 10 | 12 | 10 | 10 | 8 |

| Shrinkage(%) | 3.7~4.3 | 3.6~34.1 | 3.3~3.9 | 3.1~3.7 | 2.9~3.5 | 2.8~3.4 | 2.7~3.3 |

| Plasticity | 120~150 | 135~160 | 165~195 | 200~230 | 235~255 | 290~320 | 315~345 |

Packing

20kgs per carton, 1000kgs per pallet

Storage

Shall be put in dry and ventilate places. Validity is 6 months.

Application

Cake plates, other sealing parts.

Fumed extrusion silicone

● High extrusion speed, no bubble, smooth surface, good processing performance.

● FDA, LFGB, ROHS, REACH certificated

Application

Suitable for extruding rubber hose, sealing strip, etc.

| Items |

|

|

Value |

||

| TN-930 | TN-730 | TN-950 | TN-960 | TN-970 | |

| Appearance |

Transparent solid |

||||

| Density (g/cm3) | 1.09±0.03 | 1.1±0.03 | 1.12±0.03 | 1.13±0.03 | 1.15±0.03 |

| Hardness (Shore A) | 30±2 | 40±2 | 50±2 | 60±2 | 70±2 |

| Tensile strength (Mpa)≥ | 6 | 6.5 | 7 | 7 | 7.5 |

| Elongation(%)≥ | 450 | 350 | 250 | 200 | 150 |

| Tear strength (kN/m)≥ | 10 | 10 | 12 | 12 | 15 |

| Shrinkage(%) | 3.5~4.1 | 3.3~3.9 | 3.1~3.7 | 3.0~3.6 | 2.8~3.4 |

| Plasticity | 140~170 | 170~190 | 170~200 | 190~230 | 220~260 |

Other grades silicone we provide:

Platinum silicone rubber

Liquid silicone rubber

Fumed silicone rubber

Precipitated silicone rubber

Product detail pictures:

Related Product Guide:

We insist about the theory of growth of 'High excellent, Performance, Sincerity and Down-to-earth working approach' to offer you with great company of processing for OEM manufacturer Unvulcanized Viton - General Molding Solid Precipitated Silicone Compound – FUDI , The product will supply to all over the world, such as: Kuwait, Albania, Hungary, We critically promise that we deliver all the customers with the best quality solutions, the most competitive prices and the most prompt delivery. We hope to win a resplendent future for customers and ourselves.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!