Low price for Viton Fkm Fpm - Peroxide Curable FKM Raw Polymer – FUDI

Stock Sample is Free & Available

Low price for Viton Fkm Fpm - Peroxide Curable FKM Raw Polymer – FUDI Detail:

Peroxide curing FKM is terpolymer of hexafluoropropylene, vinylidene fluoride and tetrafluoroethylene. It has below properties compare with traditional bisphenol curable fluoroelastomer.

* Excellent flow ability and mold release.

* High tensile strength and anti rearing performance.

* Rapid curing process.

* Excellent agent resistant performance.

* Good compressing set character.

| Polyamine curing | Bisphenol curing | Peroxide curing | |

| Curing agent | Diamine | Bisphenol | TAIC |

Application

● Fuel seal

● Fuel pipe

● Shaft seal

● Turbocharger tube

● Watch band

Datasheet

| FDF351 | FDF353 | FDF533 | FDP530 | FDL530 | |

| Fluorine content % | 70 | 70 | 70 | 68.5 | 65 |

| Density (g/cm3) | 1.9 | 1.9 | 1.9 | 1.85 | 1.82 |

| Mooney Viscosity (ML (1+10)121℃) | 70±10 | 40±10 | 45±15 | 50±10 | 40±20 |

| Tensile strength after post cure (Mpa) 24h, 230℃ | ≥18 | ≥25 | ≥25 | ≥20 | ≥20 |

| Elongation at break after post cure (%)24h, 230℃ | ≥230 | ≥240 | ≥240 | ≥250 | ≥240 |

| Compression set (%) 70h, 200℃ | ≤35 | ≤20 | ≤20 | ≤25 | ≤25 |

| Application | Extrusion fuel pipes, turbocharger tube | Watch bands etc | |||

How to choose fluoroelatomer?

FKM Copolymer vs FKM Terpolymer

Copolymer: 66% fluorine content, general application, resistance to oil, fuel, heat, chemicals. Common application is o rings, oil seals, packers, gaskets, etc.

Terpolymer: higher fluorine content than copolymer 68% fluorine content. Better resistance to oil, fuel, heat, chemicals, used in harsh environment which copolymer can’t satisfy the requirements.

Bisphenol curable FPM vs Peroxide curable FPM

Bisphenol curable FPM has low compression set, offer used for o-rings, shaft seals, piston seals. Price is good.

Peroxide curable FPM has better resistance to polar solvents, steam, acids, chemicals. Price is much higher. Its often used for wearable devices, extrusion fuel hoses.

Storage

Viton precompound should be stored in a cool, dry and ventilated place. Shelf life is 24 months since production date.

Package

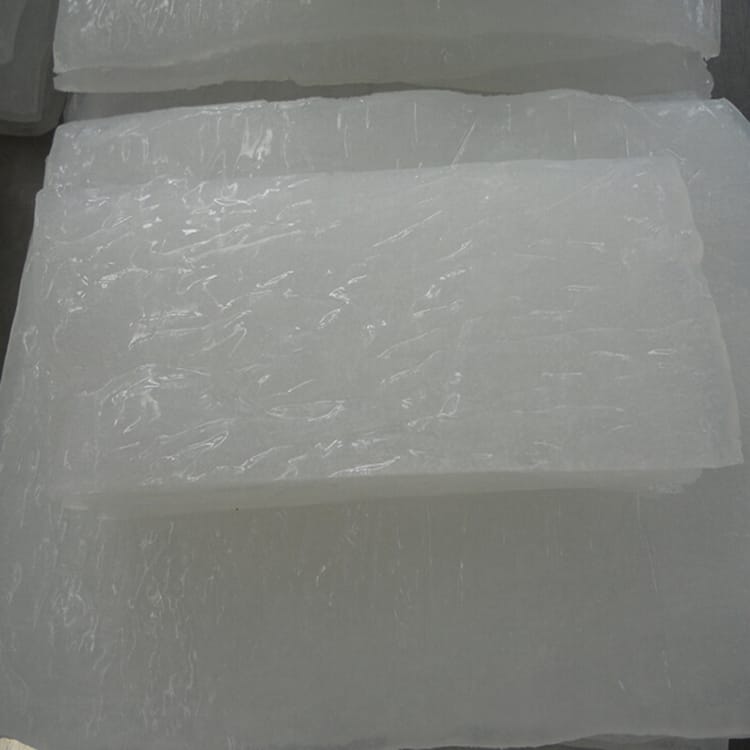

1. To prevent the compounds stick to each other, we apply PE film between each layer of FKM compounds.

2. Every 5kgs in a transparent PE bag.

3. Every 20kgs/ 25kgs in a carton.

4. 500kgs on a pallet, with strips to reinforce.

Product detail pictures:

Related Product Guide:

We provide good power in high-quality and progress,merchandising,revenue and internet marketing and operation for Low price for Viton Fkm Fpm - Peroxide Curable FKM Raw Polymer – FUDI , The product will supply to all over the world, such as: Uganda, Panama, Belarus, As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to supply our clients sincerely with qualified merchandise, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.