Low MOQ for Anel Oring Viton - Oil Resistance HNBR Raw Polymer – FUDI

Stock Sample is Free & Available

Low MOQ for Anel Oring Viton - Oil Resistance HNBR Raw Polymer – FUDI Detail:

HNBR Rubber is also known as Hydrogenated Nitrile rubber. It has good heat, oil, flame resistance. Cold tolerance is better than NBR. Main application is car synchronous belt bottom glue, high performance V band bottom glue, various automobile rubber pipe inner layer and fuel contact sealing parts etc.

Application

HNBR is widely used in aerospace, automotive industry, oil drilling, machinery manufacturing, textile & printing and other fields. It is mainly used in automobile fuel system components, auto transmission belts, drilling confinements, packer rubber tubes of oil wells, submersible pump cable sheaths of ultra-deep wells, bops, directional drillings, stator motor matching hoses of offshore oil drilling platforms, seals of aeronautics and astronautics, tank track pads, foam cushioning materials, seals of nuclear industry, hydraulic pipes, air conditioning seal products, textile & printing rubber rollers, etc

HNBR Polymer Datasheet

| Grades |

Acrylonitrile content(±1.5) |

Mooney viscosity ML1+4, 100℃(±5) |

Iodine value mg/100mg | Features and Application |

| H1818 |

18 |

80 |

12-20 |

Suitable for all kinds of low temperature and oil resistant seals, shock absorbers and gaskets, etc. |

| H2118 |

21 |

80 |

12-20 |

|

| H3408 |

34 |

80 |

4-10 |

Excellent heat resistance for use in synchronous belts, V-belts, O-rings, gaskets and seals, etc. |

| H3418 |

34 |

80 |

12-20 |

Standard medium & high ACN grade with excellent dynamic properties and processing, especially suited for synchronous belts , O-rings, gaskets, oil seals and oil industry accessories, etc. |

| H3428 |

34 |

80 |

24-32 |

Excellent permanent set at low temperature and oil resistance,especially suited for oil seals, rolls anddynamic oil field components, etc. |

| H3708 |

37 |

80 |

4-10 |

Excellent heat resistance, ozone resistance, oil resistance and etchant resistance , suitable for fuel resistant hoses, synchronous belts, sealing rings, O-rings and gaskets, etc. |

| H3718 |

37 |

80 |

12-20 |

Standard medium & high ACN grade with excellent heat resistance, ozone resistance and mediumresistance. |

| H3719 |

37 |

120 |

12-20 |

High Mooney grade similar to H3718. |

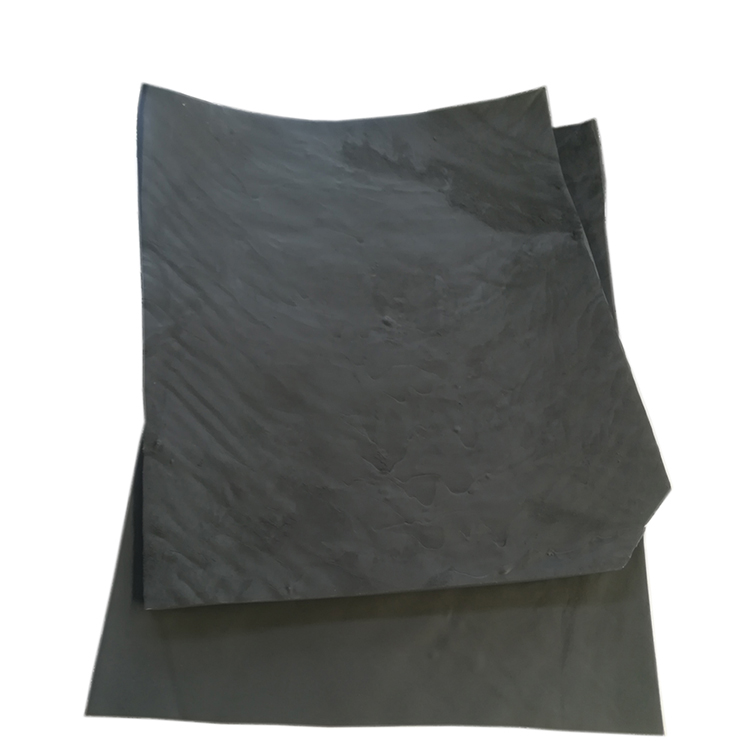

HNBR compound

● Hardness: 50~95 Shore A

● Color: Black or other colors

MOQ

Minimum order quantity is 20kgs.

Package

1. To prevent the compounds stick to each other, we apply PE film between each layer of FKM compounds.

2. Every 5kgs in a transparent PE bag.

3. Every 20kgs/ 25kgs in a carton.

4. 500kgs on a pallet, with strips to reinforce.

Product detail pictures:

Related Product Guide:

To create much more price for clients is our company philosophy; purchaser growing is our working chase for Low MOQ for Anel Oring Viton - Oil Resistance HNBR Raw Polymer – FUDI , The product will supply to all over the world, such as: Guatemala, Toronto, Hongkong, Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. Detailed Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Morocco for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!