Factory making Viton Fuel Pump Diaphragm Material - General Molding Solid Precipitated Silicone Compound – FUDI

Stock Sample is Free & Available

Factory making Viton Fuel Pump Diaphragm Material - General Molding Solid Precipitated Silicone Compound – FUDI Detail:

Silicone rubber is non-reactive, stable, and resistant to extreme environments and temperatures from −55 to 300 °C (−67 to 572 °F) while still maintaining its useful properties. It can be found in a wide variety of products, including: voltage line insulators, automotive applications; cooking, baking, and food storage products; electronics; medical devices and implants, etc.

General application silicone

● Good processing performance

● Good stability

● Good resilience

● Good fluidity

● Fast curing speed

● Good mould-releasing

● FDA, Rohs certified

Technical Data

| Items |

|

|

Value |

||||

| TN-720 | TN-730 | TN-740 | TN-750 | TN-760 | TN-770 | TN-780 | |

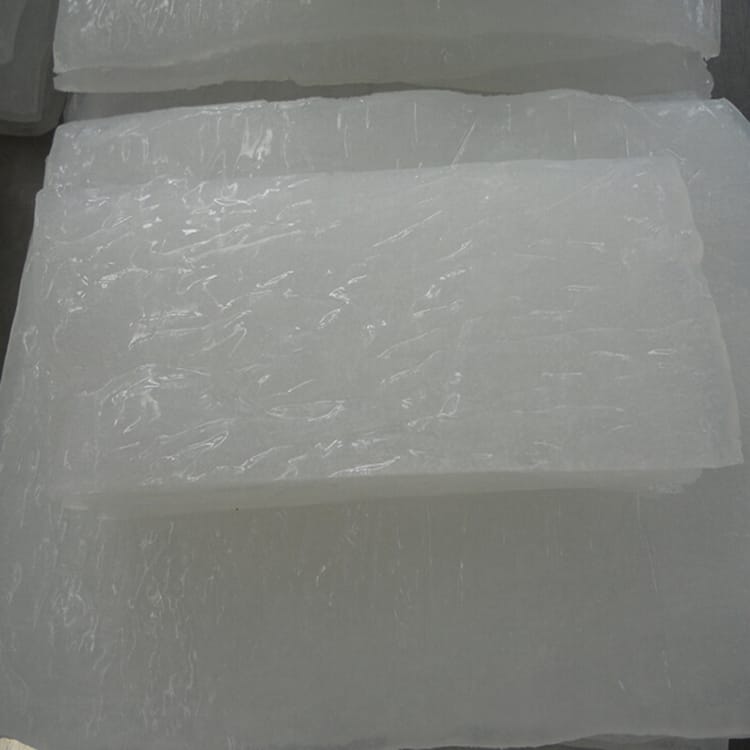

| Appearance |

Translucent, smooth surface, no impurities |

||||||

| Density (g/cm3) | 1.06±0.03 | 1.08±0.03 | 1.12±0.03 | 1.15±0.03 | 1.19±0.03 | 1.22±0.03 | 1.24±0.03 |

| Hardness (Shore A) | 20±2 | 30±2 | 40±2 | 50±2 | 60±2 | 70±2 | 80±2 |

| Tensile strength (Mpa)≥ | 4.0 | 6.0 | 6.5 | 7.5 | 7.5 | 7.0 | 7.0 |

| Elongation(%)≥ | 750 | 650 | 550 | 450 | 400 | 280 | 150 |

| Tear strength (kN/m)≥ | 8 | 10 | 10 | 12 | 10 | 10 | 8 |

| Shrinkage(%) | 3.7~4.3 | 3.6~34.1 | 3.3~3.9 | 3.1~3.7 | 2.9~3.5 | 2.8~3.4 | 2.7~3.3 |

| Plasticity | 120~150 | 135~160 | 165~195 | 200~230 | 235~255 | 290~320 | 315~345 |

Packing

20kgs per carton, 1000kgs per pallet

Storage

Shall be put in dry and ventilate places. Validity is 6 months.

Application

Cake plates, other sealing parts.

Fumed extrusion silicone

● High extrusion speed, no bubble, smooth surface, good processing performance.

● FDA, LFGB, ROHS, REACH certificated

Application

Suitable for extruding rubber hose, sealing strip, etc.

| Items |

|

|

Value |

||

| TN-930 | TN-730 | TN-950 | TN-960 | TN-970 | |

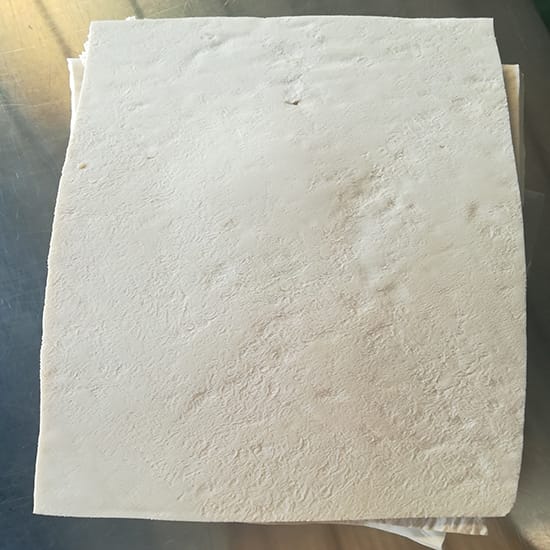

| Appearance |

Transparent solid |

||||

| Density (g/cm3) | 1.09±0.03 | 1.1±0.03 | 1.12±0.03 | 1.13±0.03 | 1.15±0.03 |

| Hardness (Shore A) | 30±2 | 40±2 | 50±2 | 60±2 | 70±2 |

| Tensile strength (Mpa)≥ | 6 | 6.5 | 7 | 7 | 7.5 |

| Elongation(%)≥ | 450 | 350 | 250 | 200 | 150 |

| Tear strength (kN/m)≥ | 10 | 10 | 12 | 12 | 15 |

| Shrinkage(%) | 3.5~4.1 | 3.3~3.9 | 3.1~3.7 | 3.0~3.6 | 2.8~3.4 |

| Plasticity | 140~170 | 170~190 | 170~200 | 190~230 | 220~260 |

Other grades silicone we provide:

Platinum silicone rubber

Liquid silicone rubber

Fumed silicone rubber

Precipitated silicone rubber

Product detail pictures:

Related Product Guide:

Our company insists all along the quality policy of "product quality is base of enterprise survival; customer satisfaction is the staring point and ending of an enterprise; persistent improvement is eternal pursuit of staff" and the consistent purpose of "reputation first, customer first" for Factory making Viton Fuel Pump Diaphragm Material - General Molding Solid Precipitated Silicone Compound – FUDI , The product will supply to all over the world, such as: Guatemala, United States, Latvia, By integrating manufacturing with foreign trade sectors, we can present total customer solutions by guaranteeing the delivery of right merchandise to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified products and the control of the industry trend as well as our maturity before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.