Alkali Steam Resistance FEPM Aflas Compound

Stock Sample is Free & Available

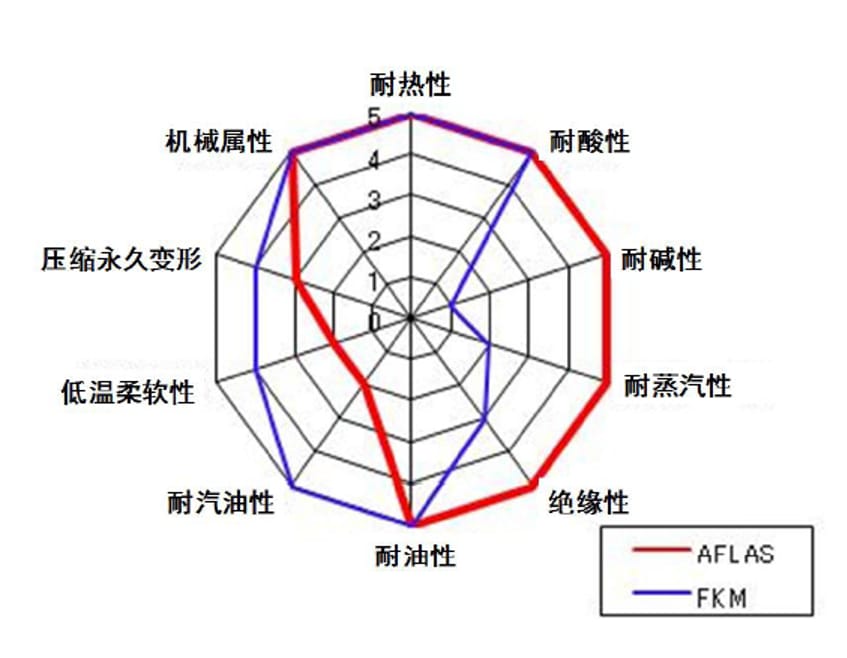

Compared to general fluoro rubber, Aflas FEPM has better resistance to alkali and acid. Better electrical insulation and impermeability.

● Hardness: 75 Shore A

● Color: Black, brown

● Application: make O-rings, irregular-shaped rings, gaskets

● Advantage: better resistance to alkali and acid. Better electrical insulation and impermeability.

● Disadvantage: processing is difficult

Technical Data

| Items | Unit | FD4675 |

|

Typical Properties |

||

| Fluorine Content: | % | 57 |

| Gravity | g/cm3 | 1.65 |

| Color | Black or any other colors | |

|

Typical Curing Properties: |

||

| Monsanto Moving Die Rheometer 【MDR2000®】100cpm, 0.5°Arc,6 minutes@177℃ | ||

| ML, Minimum Torque, 0.23 | N·m | 0.24 |

| MH, Maximum Torque, | N·m | 0.82 |

| ts2【Time to 2 inch-lb rise from minimum】 | 2′45″ | |

| t90【Time to 90% cure】 | 4′50″ | |

|

Typical Physical Properties |

||

| Press Cure 10 minutes@170℃Post Cure 5 hours@200℃ | ||

| Tensile Strength【ASTM D412】 14.5 | Mpa | 13 |

| Elongation at break【ASTM D412】 | % | 300 |

| Hardness Shore A【ASTM D 2240) | 74 | |

| Post Cure 20 hours@200℃ | ||

| Tensile Strength【ASTM D412】 14.5 | Mpa | 15.8 |

| Elongation at break【ASTM D412】 | % | 260 |

| Hardness Shore A【ASTM D 2240) | 77 | |

| Compression set【ASTM D395 Method B,24h@200℃】 | % | 15 |

Storage

FKM rubber material should be stored in a cool, dry and ventilated place. Shelf life is 12 months since production date.

Package

1. To prevent the compounds stick to each other, we apply PE film between each layer of FKM compounds.

2. Every 5kgs in a transparent PE bag.

3. Every 20kgs/ 25kgs in a carton.

4. 500kgs on a pallet, with strips to reinforce.