2022 High quality Fvmq Material Properties - Low Compression Set FVMQ Compound – FUDI

Stock Sample is Free & Available

2022 High quality Fvmq Material Properties - Low Compression Set FVMQ Compound – FUDI Detail:

Fluorosilicone FVMQ rubber is also known as fluorinated silicone rubber. It combines the advantages of both silicone rubber and fluoro rubber. It can be used in aerospace, vehicles, ships, electronic communications, precision instruments, petrochemical, medical and health fields etc.

● Hardness: 30-80 Shore A

● Color: Blue, red, or tailor made

● Temperature resistance: -60-225℃

● Characters: excellent oil, solvent resistance, good high and low temperature resistance, weather resistance, good resilience

Low compression set and high rebound grade fluorosilicone compound

| Items | Unit | Testing |

Value |

||||

| Grade | G1040 | G1050 | G1060 | G1070 | G1080 | ||

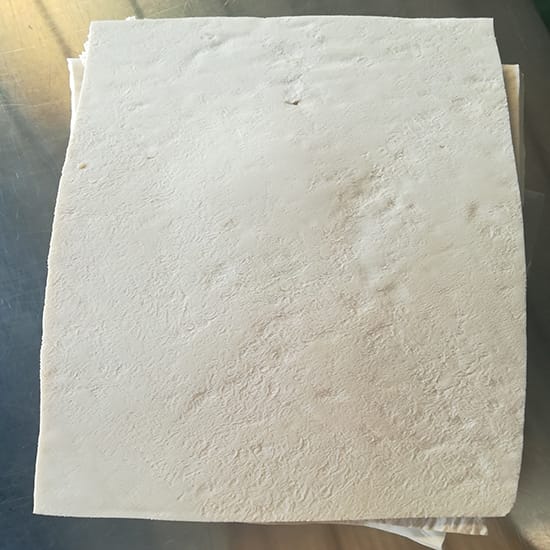

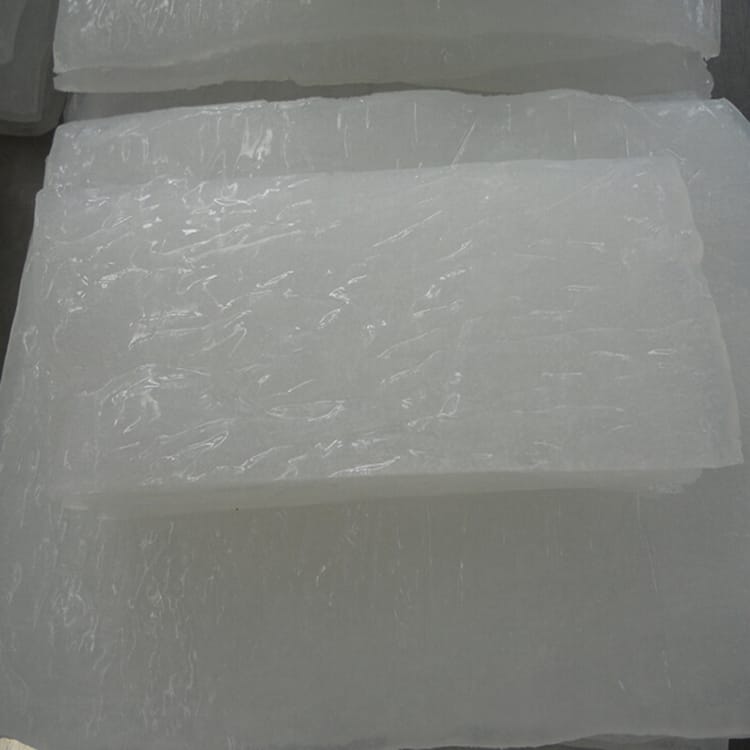

| Appearance | Visual | Translucent, smooth surface, no impurities | |||||

| Hardness | ShA | ASTIM D2240 | 40±5 | 50±5 | 60±5 | 70±5 | 80±5 |

| Tensile strength (Die C) | Mpa | ASTM D412 | 10.2 | 10.2 | 10.2 | 10.2 | 8.9 |

| Elongation (Die C) | % | ASTM D412 | 410 | 355 | 332 | 270 | 205 |

| Tear strength (Die B) | KN/m | ASTM D624 | 17 | 17 | 18 | 18 | 17 |

| Compression set(22h @177℃) | % | ASTM D395 | 6.1 | 6.1 | 6.3 | 6.8 | 6.9 |

| Resilience | % | ASTM D2632 | 31 | 32 | 32 | 32 | 32 |

| Volume change(72h @23℃) | % | ASTM D471 | -20 | -20 | -20 | -20 | -20 |

| Tensile strength change (72h @23℃) | % | ASTM D471 | -20 | -20 | -20 | -20 | -20 |

| Elongation change(72h @23℃) | % | ASTM D471 | -20 | -20 | -20 | -20 | -20 |

| Heat aging tensile(72h @225℃) | ASTM D573 | -17 | -17 | -17 | -17 | -17 | |

| TR-10 | ℃ | -45 | -45 | -45 | -45 | -45 | |

High tear strength grade fluorosilicone compound

| Items | Unit | Testing |

Value |

||||

| Grade | HT2040 | HT2050 | HT2060 | HT2070 | HT2080 | ||

| Appearance | Visual | Translucent, smooth surface, no impurities | |||||

| Hardness | ShA | ASTIM D2240 | 40±5 | 50±5 | 60±5 | 70±5 | 80±5 |

| Tensile strength (Die C) | Mpa | ASTM D412 | 11.5 | 11.6 | 11.7 | 9.3 | 8.7 |

| Elongation (Die C) | % | ASTM D412 | 483 | 420 | 392 | 322 | 183 |

| Tear strength (Die B) | KN/m | ASTM D624 | 41 | 43 | 43 | 35 | 30 |

| Compression set(22h @177℃) | % | ASTM D395 | 13 | 14 | 16 | 17 | 20 |

| Volume change(Fuel C, 72h @23℃) | % | ASTM D471 | 17 | 17 | 17 | 17 | 17 |

| Tensile strength change (Fuel C, 72h @23℃) | % | ASTM D471 | -20 | -20 | -20 | -20 | -20 |

| Elongation change(Fuel C, 72h @23℃) | % | ASTM D471 | -20 | -20 | -20 | -20 | -20 |

| Heat aging tensile(72h @225℃) | ASTM D573 | -20 | -20 | -20 | -20 | -20 | |

MOQ

Minimum order quantity is 20kgs.

Package

20kgs per carton, 500kgs per pallet.

Product detail pictures:

Related Product Guide:

To be a result of ours specialty and service consciousness, our enterprise has won an excellent status between buyers all around the globe for 2022 High quality Fvmq Material Properties - Low Compression Set FVMQ Compound – FUDI , The product will supply to all over the world, such as: French, Paris, New Zealand, We have gained a lot of recognition among customers spread all across the world. They trust us and always give repetitive orders. Furthermore, mentioned below are some of the major factors that have played significant role in our tremendous growth in this domain.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!