2022 High quality Fvmq Material Properties - Low Compression Set FVMQ Compound – FUDI

Stock Sample is Free & Available

2022 High quality Fvmq Material Properties - Low Compression Set FVMQ Compound – FUDI Detail:

Fluorosilicone FVMQ rubber is also known as fluorinated silicone rubber. It combines the advantages of both silicone rubber and fluoro rubber. It can be used in aerospace, vehicles, ships, electronic communications, precision instruments, petrochemical, medical and health fields etc.

● Hardness: 30-80 Shore A

● Color: Blue, red, or tailor made

● Temperature resistance: -60-225℃

● Characters: excellent oil, solvent resistance, good high and low temperature resistance, weather resistance, good resilience

Low compression set and high rebound grade fluorosilicone compound

| Items | Unit | Testing |

Value |

||||

| Grade | G1040 | G1050 | G1060 | G1070 | G1080 | ||

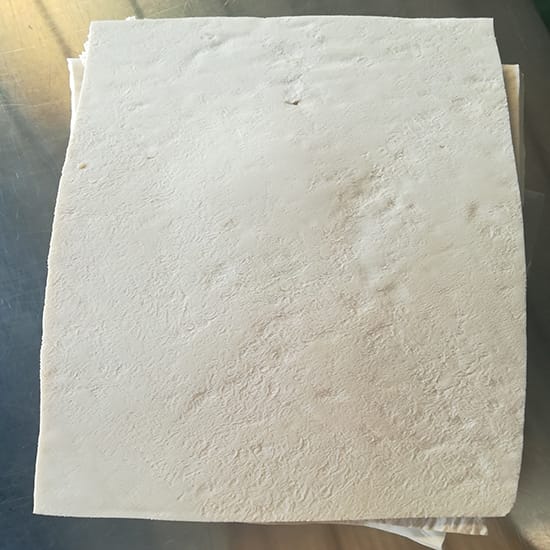

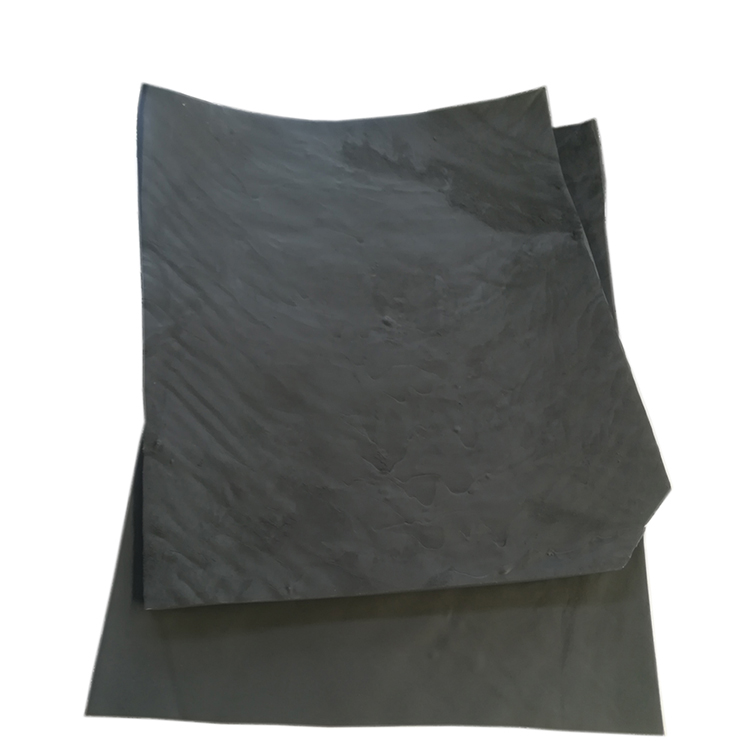

| Appearance | Visual | Translucent, smooth surface, no impurities | |||||

| Hardness | ShA | ASTIM D2240 | 40±5 | 50±5 | 60±5 | 70±5 | 80±5 |

| Tensile strength (Die C) | Mpa | ASTM D412 | 10.2 | 10.2 | 10.2 | 10.2 | 8.9 |

| Elongation (Die C) | % | ASTM D412 | 410 | 355 | 332 | 270 | 205 |

| Tear strength (Die B) | KN/m | ASTM D624 | 17 | 17 | 18 | 18 | 17 |

| Compression set(22h @177℃) | % | ASTM D395 | 6.1 | 6.1 | 6.3 | 6.8 | 6.9 |

| Resilience | % | ASTM D2632 | 31 | 32 | 32 | 32 | 32 |

| Volume change(72h @23℃) | % | ASTM D471 | -20 | -20 | -20 | -20 | -20 |

| Tensile strength change (72h @23℃) | % | ASTM D471 | -20 | -20 | -20 | -20 | -20 |

| Elongation change(72h @23℃) | % | ASTM D471 | -20 | -20 | -20 | -20 | -20 |

| Heat aging tensile(72h @225℃) | ASTM D573 | -17 | -17 | -17 | -17 | -17 | |

| TR-10 | ℃ | -45 | -45 | -45 | -45 | -45 | |

High tear strength grade fluorosilicone compound

| Items | Unit | Testing |

Value |

||||

| Grade | HT2040 | HT2050 | HT2060 | HT2070 | HT2080 | ||

| Appearance | Visual | Translucent, smooth surface, no impurities | |||||

| Hardness | ShA | ASTIM D2240 | 40±5 | 50±5 | 60±5 | 70±5 | 80±5 |

| Tensile strength (Die C) | Mpa | ASTM D412 | 11.5 | 11.6 | 11.7 | 9.3 | 8.7 |

| Elongation (Die C) | % | ASTM D412 | 483 | 420 | 392 | 322 | 183 |

| Tear strength (Die B) | KN/m | ASTM D624 | 41 | 43 | 43 | 35 | 30 |

| Compression set(22h @177℃) | % | ASTM D395 | 13 | 14 | 16 | 17 | 20 |

| Volume change(Fuel C, 72h @23℃) | % | ASTM D471 | 17 | 17 | 17 | 17 | 17 |

| Tensile strength change (Fuel C, 72h @23℃) | % | ASTM D471 | -20 | -20 | -20 | -20 | -20 |

| Elongation change(Fuel C, 72h @23℃) | % | ASTM D471 | -20 | -20 | -20 | -20 | -20 |

| Heat aging tensile(72h @225℃) | ASTM D573 | -20 | -20 | -20 | -20 | -20 | |

MOQ

Minimum order quantity is 20kgs.

Package

20kgs per carton, 500kgs per pallet.

Product detail pictures:

Related Product Guide:

Our products are greatly acknowledged and reliable by users and may fulfill repeatedly shifting financial and social wants for 2022 High quality Fvmq Material Properties - Low Compression Set FVMQ Compound – FUDI , The product will supply to all over the world, such as: UK, Guinea, Venezuela, We've been consistently broadening the market within Romania in addition to preparation punching in extra premium quality merchandise connected with printer on t shirt so that you can Romania. Most people firmly believe we've the whole capacity to provide you happy solutions.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.